Book your future event

21-24 September 2022

Meccanotecnica’s head office,

Torre de’ Roveri - Bergamo (Italy).

Meccanotecnica’s head office,

Torre de’ Roveri - Bergamo (Italy).

The “Open House” style industrial event aims to show visitors the

latest technological innovations in bookbinding and

share ideas and projects about the book industry’s future.

Every day, live demos will show you how to produce

books more efficiently and cost-effectively.

At the heart of Lombardy, come to Bergamo for

four days of networking

and experience our high-performance digital and offset book finishing

solutions.

Since the event is by invitation only, submit your

request if you are interested in attending, and our team will contact

you.

Meccanotecnica reserves the right to evaluate the requests before acceptance.

The last edition of the event in 2018 has seen visitors from all over the world:

Be part of itTotal Visitors

Countries

Books produced

Production lines

Growing market competitiveness and price pressure is pushing digital

printers and binders towards solutions capable of increasing

efficiency and productivity while at the same time reducing costs.

How can we be successful in a market that sees print runs

progressively decline?

The answer to all these challenges is AUTOMATION, the game-changer and

the key to optimize production processes.

There is a new challenge, however, one that seems to be coming faster

than most had anticipated: the lack of qualified labour to run

printing and binding plants.

How can we address this issue and remain competitive and profitable?

The answer is not easy. Still, new strategies can help printers run

the bindery with fewer operators thanks to the integration of the

production processes or a transition towards digital printing and the

adoption of new business models.

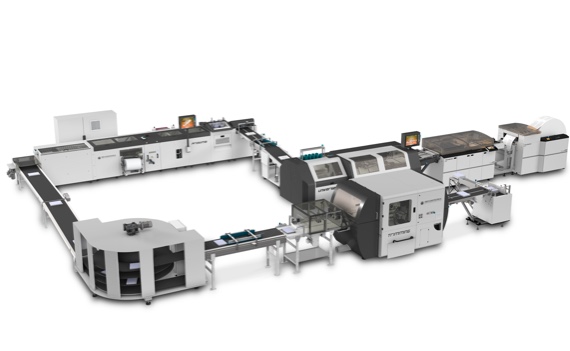

The integration of the finishing processes brought by the Uniplex and

Multiplex lines addresses this challenge increasing productivity,

reducing the workforce, and lowering the unitary cost of the book.

These automatic gathering and sewing lines provide the most efficient

way of producing books, eliminating intermediate handling and

non-productive processes such as storage and transport of pre-gathered

signatures.

In the digital production of books, the choice between sheet-fed or

web-fed finishing is based primarily on the production workflow and

the variety of formats and substrates to be handled; factors such as

average run length, size variability between titles, paper types, and

weights, and overall production volumes are all elements to be

considered and evaluated.

The automatic book sewing machines for digital printing of the

UNIVERSE SERIES allow book manufacturers to precisely find the correct

version for their business model, helping them open new market

opportunities, increase efficiency, and reduce costs.

The combination of UNIVERSE, automatic book sewing machine, the back

gluer PROXIMA for hardcover book preparation and the three-knife

trimmer positions itself as an effi¬cient and cost-effective solution

for the production of high-quality books in short-runs.